Extrusion line downtime can be expensive. To reduce downtime, it’s important to develop and...

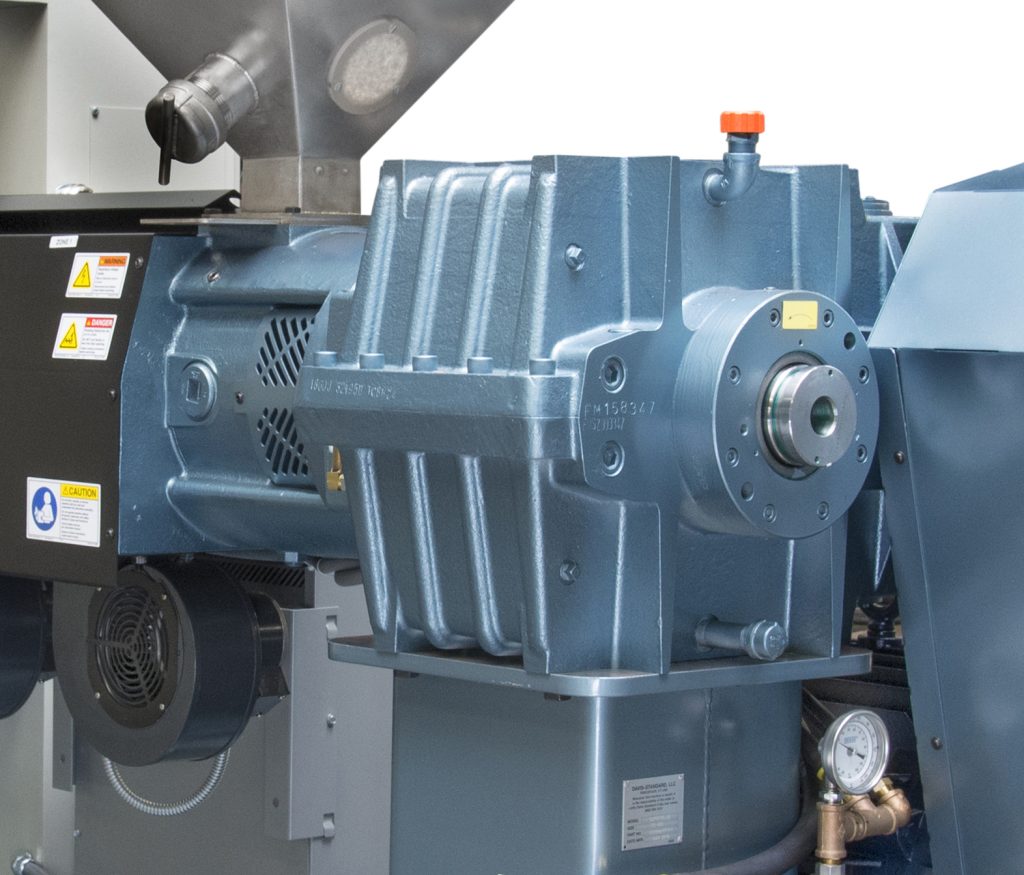

Preventive Maintenance for Davis-Standard Gear Reducers – Oil Selection

In the first two blogs of this series, we outlined oil change intervals and the process for flushing the gear reducer. In this final blog post of the series, we’ll provide guidance on oil selection.

Always follow the maintenance information in the manual provided with your equipment. This blog summarizes general preventative maintenance for the gear reducer.

Selecting the right lubricant for your gear reducer is important to long-term operational success. The demand on your gear reducer is significant; the gear teeth need to withstand high contact stress to transmit the torque your process application requires. Lubricant manufacturers have addressed this by developing higher quality oils to help carry increased loads safely. It’s also important to evaluate operating conditions to determine the best option.

For example, what are the environmental considerations? Heat, dust, moisture, and other variables impact lubrication.

When selecting the right lubricant, check the oil type, viscosity, and quantity stamped on the reducer nameplate. This will be based upon application information provided at the time of purchase. For normal operating conditions with ambient temperatures between 50°F (10°C) and 104°F (40°C), a quality mineral gear oil with rust and oxidation inhibitors is recommended.

If you are seeking greater energy efficiency, you may want to consider polyalphaolefin-based synthetic R&O oils. Polyalphaolefins are compatible with mineral oil. Oil change intervals should remain the same as they are for mineral oil unless justified by a routine oil analysis.

If the application information has changed, or you are unsure what oil to use, contact Davis-Standard for assistance to verify the oil type and viscosity selection.

We hope this preventative maintenance series for gear reducers has been helpful to you. Have questions or comments about this blog? Write a comment below.

Davis-Standard’s extensive service and maintenance capabilities are equipped to support you for this task and any other aftermarket needs. We can also customize a service or maintenance package to fit your requirements. Contact us here if you’d like a tailored package.

Any other questions or inquiries, e-mail marketing.