Under normal processing conditions and with properly designed equipment, underwater pelletizing...

Maximizing Your Underwater Pelletizer Performance

Do you know if your underwater pelletizer is providing you with the desired pellet quality and output? It is not uncommon for many to assume all is well, only to realize that die plate performance is not up to par. The good news is, checking is easy.

In most cases, these issues are linked to the number of open and flowing orifice holes in the die plate. Maintaining the free-flow of product is essential to achieve quality pellets and higher outputs. When these orifices become partially or completely frozen off, issues ensue. This is especially true when processing difficult products and when equipment differences exist.

How can you measure performance to ensure this is not the case? Our team has developed a procedure just for you! Using simple equations and a step-by-step process, our pellet count procedure measures the number of pellets that should be created versus the actual number.

Davis-Standard Pellet Count Procedure

Use this procedure to determine the percentage or number of open and flowing orifices in an underwater pelletizer die plate.

(1) Count out at least 50 pellets from a pellet sample taken at the same point in time that the pelletizer shaft speed and total production output were noted.

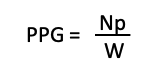

(2) Divide the number of pellets counted by total weight (in grams) to measure pellets per gram.

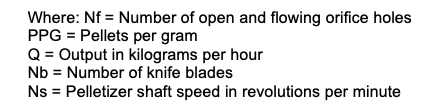

Measure the Percentage of Open and Flowing Orifices

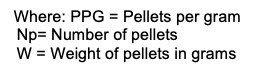

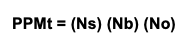

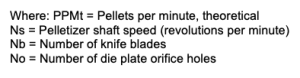

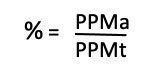

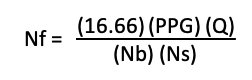

(1) Determine the theoretical number of pellets that should have been produced per unit of time.

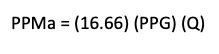

(2) Determine the actual number of pellets produced per unit of time.

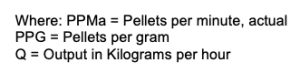

(3) Calculate the percentage of open and flowing holes.

Measure the Number of Open and Flowing Orifices

NOTE: The accuracy of the measured values will greatly affect the results.

Upon determining actual performance, you can then make other modifications as needed to improve outcomes. After all, a correctly designed underwater pelletizer operating under ideal process set-up conditions should produce high-quality pellets with great efficiency.

If you have a competitor’s machine or an older Davis-Standard underwater pelletizer, take the challenge and compare the results to newer Davis-Standard’s pelletizer designs. You might be surprised at what you discover.

For further information on how to improve your pelletizer performance, scan the QR code to contact Sarah Eisel, Product Manager of Pelletizing Equipment.

Or contact us here.