One of the most effective ways for extrusion and converting processors to boost performance,...

Feedscrew and Design Truths for Improved Longevity, Part I

At Davis-Standard, we love talking feedscrews and process design. In this blog, we’re going to talk about the three types of feedscrew wear, the causes of that wear and corrective actions to eliminate it. In the next blog, we’ll get even more specific using examples of a groove feed and smooth bore extruder to show how the feedscrew plus process design influences equipment longevity.

There are three types of feedscrew wear: abrasive, adhesive and corrosive. Depending on the polymers you process, these types of wear can be costly and frustrating.

Abrasive wear is categorized by the contact environment and the type of contact. There is two-body abrasive wear that takes place when hard particles from a filled polymer or grit eliminate material from the opposing surface. And there is three-body wear when particles are unconstrained and free to slide down and roll on the surface while under pressure. Ultimately these types of wear cause a fragmentation or cutting action on the feedscrew, eroding the surface.

Causes: Hard particles in the polymer matrix

Corrective Action: Use harder materials of construction (HIP materials) and protective coatings (HVOF).

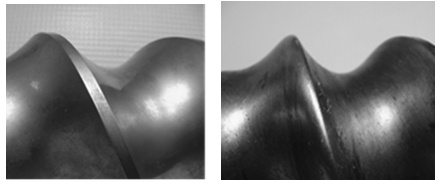

Figure 1: Abrasive Wear example. New screw on the left, and screw with abrasive wear on the right.

Adhesive wear occurs when there is metal-to-metal contact of two surfaces in relative motion. The small peaks and ridges of the feedscrew collide with the peaks on a twin feedscrew or with the barrel itself, leading to an instantaneous micro-weld. This weld is fractured due to the relative motion of the two surfaces resulting in a “high” spot that will eventually break off. This process continues as the two surfaces alternately weld and tear material from each other.

Causes: Metal-to-metal contact due to poor alignment, an overhung load, thermal expansion, high discharge pressures, incorrect operating conditions or a bent feedscrew

Corrective Action: Use of borescoping equipment, regular maintenance, proper support for downstream and upstream equipment (screen changers, melt pumps and feed systems) and correct installation practices are essential.

Figure 2: Adhesive wear example. New screw to the left and top of a screw flight showing adhesive wear to the right.

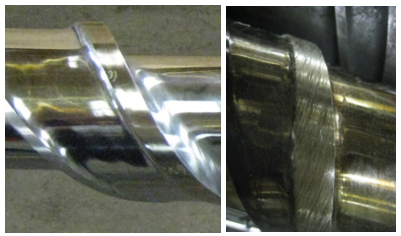

Corrosive wear results when a corrosive material attacks the surface metal. Corrosive polymers such as some PVC’s, corrosive flame-retardants and fluorocarbons are common culprits. The feedscrew and barrel are essentially destroyed through an unintentional chemical or electrochemical action causing pitting and surface roughness.

Causes: Polymers that evolve during processing or degrade during heat-up or shutdown; EVA, EMA, EMAA, EAA and other ionomers; those that contain chlorine and/or fluorine such as PVC, CPVC and FEP, PVDF, ETFE, ECTFE

Corrective Action: Select the appropriate materials of construction or apply protective coatings that do not react with the polymer or degradation of products by the polymer (ie. nickel coatings, high-nickel alloys).

Figure 3: Two examples of corrosive wear.

What if you take the corrective measures above and still experience excessive wear? It happens. The next blog will share how process design comes into play.

Have questions? Comment below or e-mail marketing at marketing@davis-standard.com.