In the first blog of this series, we outlined oil change intervals. In this blog, we move on to the...

The Feedscrew and Barrel Factor

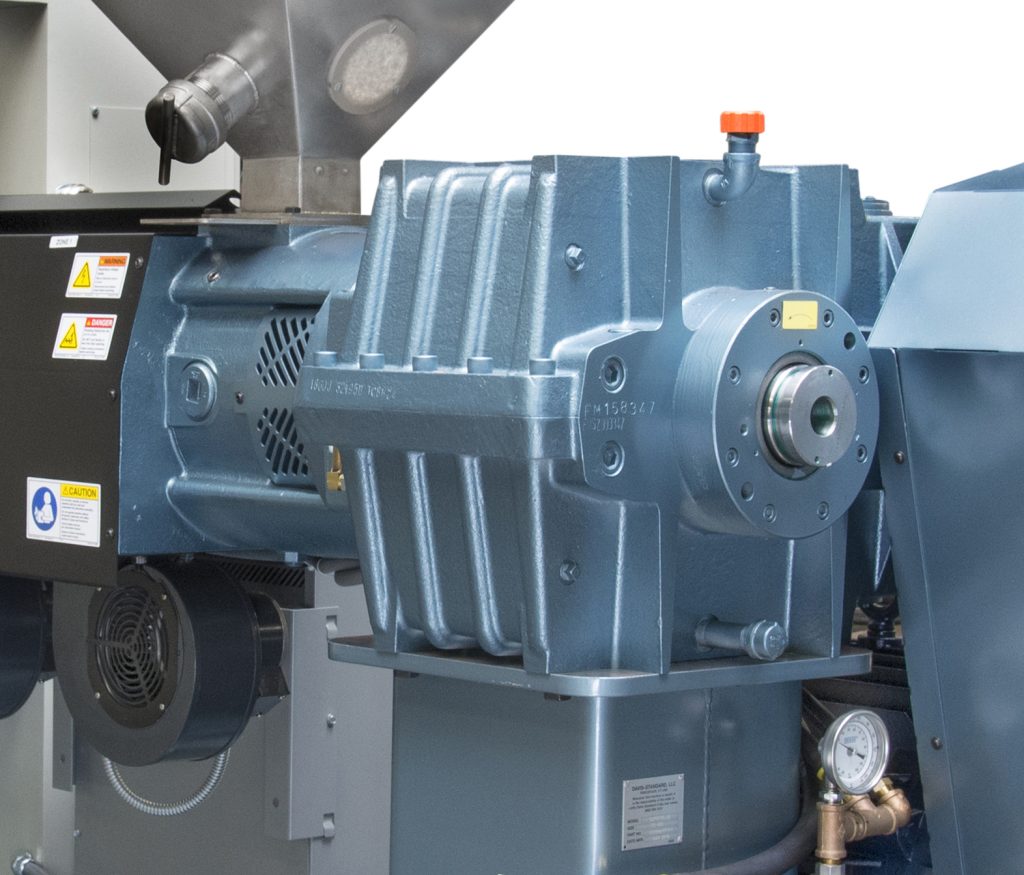

How important are feedscrews and barrels to profitability? When you consider product quality, target outputs and overall process performance, the answer is VERY important. Ensuring you get the most out of your investment involves understanding the causes of wear and selecting the right barrel and feedscrew base metal and surface constructions.

Causes of wear

Common Causes of Adhesive Wear (metal-to-metal contact):

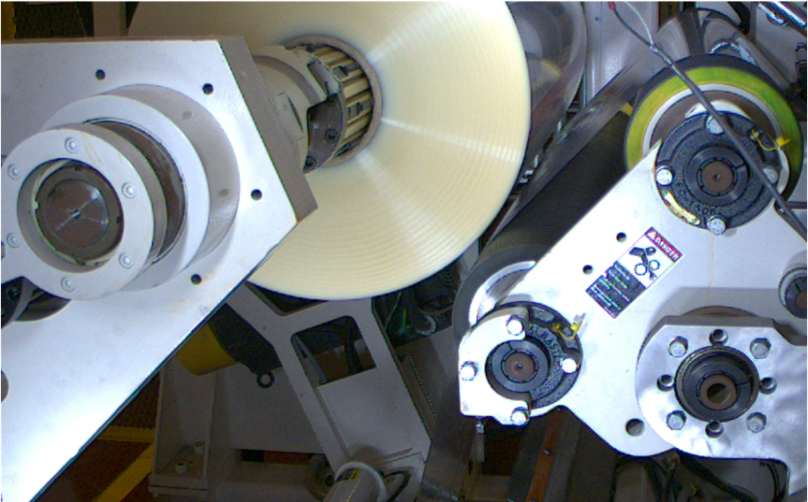

- Straightness of barrel and screw

- Alignment of drive, barrel, feedsection, and feedscrew

- Screw design

- Lack of uniformity of barrel heating

- Screw surface treatment and barrel liner finish being wrongly matched

- Improper support of the extruder barrel (common with extended L/D ratios)

- Unsupported dies at the end of the barrel

- Excessive head pressure

Common Causes of Abrasive Wear:

- Processing polymers with fillers such as talc, calcium chloride, glass fibers, barium ferrite and titanium oxide

- Processing silicones

Common Causes of Corrosive Wear (material attacking the surface metals)

- Processing of corrosive polymers such as some PVC’s, corrosive flame-retardants and fluorocarbons

Preventing premature wear

Make sure screw and barrel material of construction are matched and that one is not trying to induce premature wear in the other.

Only use extrusion barrels and screws with the right base metals and surface hardness for the abrasive and/or corrosive nature of your application. Davis-Standard offers three primary bimetallic grades for barrel treatments: DS1000, DS6000 and DS8000.

- The DS1000 is iron-based for general purpose wear environments that are non-corrosive.

- The DS6000 is nickel-based for processing corrosive compounds such as those with flame retardants, fluoropolymers and high-temperature resins.

- The DS8000 is a nickel-based alloy engineered with a high percentage of tungsten carbide particles suspended within its matric. We recommend this for applications requiring highly corrosive filled or reinforced compounds as well as fluoropolymers and high-temperature resins.

Feedscrew finishes range from high-quality steel for standard applications to Inconel, Hastelloy and Duranickel for highly corrosive applications. Heat treatments such as flame hardening and nitride may also be necessary. To improve wear characteristics on the flight tips, Davis-Standard can inlay a variety of substrates such as stellites and Colmony 83 for improved abrasion resistance. Root surface treatments such as chrome and spray coatings are used for extreme wear conditions.

It’s essential to check for component straightness and machine misalignment on an ongoing basis. You’ll also want to make sure you have the right screw geometry for your application.

For more information regarding feedscrews and barrels, please contact marketing@davis-standard.com.