Welcome to the fourth blog of our winder series featuring the insight of our

Meeting Productivity and Profitability Challenges in Winding | Winding Series Part I

Winding Series #1

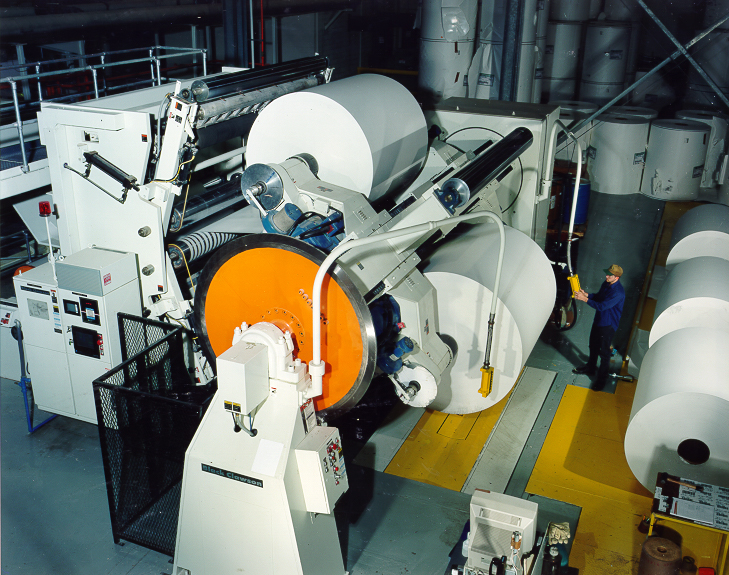

Thanks to our in-house winding expert, Duane Smith, we’ll be doing a series of blogs on the intricacies and economics of winding technology. In this first blog, Duane offers insight on how you can increase productivity, lower production costs, decrease scrap rates and shorten production cycles by incorporating slitting and winding processes into a production line.

When looking for ways to meet or exceed productivity and profitability goals, every non-value added activity must be eliminated. When winding rolls consider the fact that each time a roll of material is handled, the chance of roll damage is increased. In a typical scenario, a roll is loaded into the unwind of a slitting and rewinding operation and multiple layers of the outside diameter are removed. The sheet is then threaded through another machine and jogged until the sheet runs true. After that, the slitters are engaged, and the slit webs are brought to the new cores. All of this generates waste and lost product. Next, the webs are unwound, tensioned or stretched, and rewound at varying tensions (typically +/- 10 percent of the tension setpoint) during acceleration and deacceleration times. This is not efficient or cost-effective.

One of the best ways to simplify this process and boost profitability is to slit and wind shippable quality rolls as part of the production line. Moving to an in-line arrangement could save you between $0.05 and $0.10 per pound of production cost. Just as important, by slitting and winding high-quality rolls with proper density control on your process, quality deviations such as moisture or caliper more easily identified and corrected.

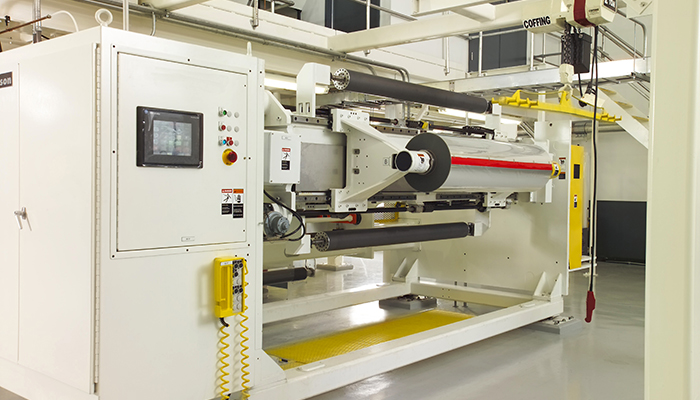

The good news? There is technology available to help you achieve your goals. When looking to purchase or upgrade equipment, consider the following:

- Consistency is king. For an in-line slitting operation, the process control system must be equipped with capabilities to manage and promote process consistency. In order to successfully in-line slit products, the consistency of the caliper and basic weight must be within the extensibility of the material.

- Win with automation. Automated slitter positioning systems and automated roll and shaft handling systems deliver fast and efficient set-width changes, roll changes and recoring.

- Speed and accuracy. New transfer systems enable straight-line cuts and transfers of the slit web directly to the new cores. Stationary knife transfer concepts provide 100 percent roll change consistency regardless of web width and speed of the operation. These provide the important clean web starts on new cores.

- TNT is key! High-quality rolls require that the first and last wraps are as good as those in-between. Controlled tension, nip and torque (TNT) must be maintained throughout the entire winding cycle, including the roll change. (We’ll cover more on this in another blog!)

- Versatility = Value. Selecting the right winder and auxiliary equipment is key to achieving high productivity and profitability on your quality web producing operation. This is discussed in the Davis-Standard tech tips entitled “Guide to Selecting the Best Winding Process” and “Pros and Cons of In-Line Slitting”. Contact us for a copy of these tech tips.

In the coming blogs, we’ll discuss productivity requirements for continuous unwinding and splicing, the art of winding good rolls, challenges in winding flexible packaging film and guidelines for rolls used in web handling.

Have questions? Comment below or e-mail marketing at marketing@davis-standard.com.