Your feedscrew is stuck…now what? Never fear! First thing’s first, follow the instructions in your...

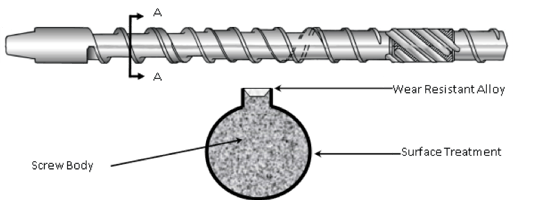

Feedscrew Wear Guidelines for Best Results

We hope you have enjoyed our blog series on feedscrews that we posted in 2019. If you have not seen those yet, you can find them below. There is excellent information on causes of wear and improving longevity to get the most benefit from your feedscrew investment.

The Feedscrew and Barrel Factor

Feedscrew and Design Truths for Improved Longevity, Part I

Feedscrew and Design Truths for Improved Longevity, Part II

Feedscrew and Design Truths for Improved Longevity, Part III

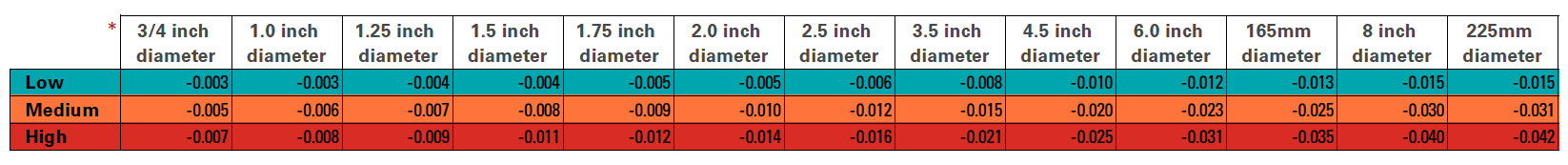

Expanding on our series, we provide below basic wear guidelines to assist you in knowing when to rebuild or replace your feedscrew. You can monitor wear by taking advantage of borescoping services at least once a year. That service will indicate diametrical wear numbers that can be used to monitor wear and help avoid problems in the field.

The low number will cause a decrease in your output at a given rpm.

The medium number indicates that performance should be monitored more closely with preparations to rebuild or replace the feedscrew.

With the high number, we suggest you rebuild or replace the feedscrew.

Please note: The foregoing are guidelines and specific cases can vary

*For exact diameter of your feedscrew (new/not used), please reach out to your regional sales manager.

Would you like to schedule a borescoping service with our team? Contact us!

For any other questions, comment below or e-mail marketing.