In part I of this blog, we reviewed the three types of feedscrew wear, the causes of that wear and...

Feedscrew and Design Truths for Improved Longevity, Part III

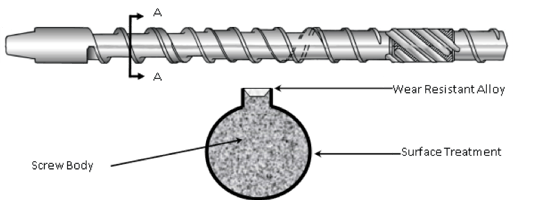

In part two of this blog, we covered the importance of the feedscrew materials of construction. In this blog, we’ll discuss how surface treatments or screw coatings can be used to improve screw wear.

The wear and corrosion resistance of the screw body can be improved by applying surface coatings. These solutions encompass everything from thin metal coatings that protect the surface from the normal wear and tear of cleaning and processing to high- performance materials used to minimize severe abrasive wear. Chrome and nickel plating are widely used for standard applications. For more challenging applications, coatings applied by High-Velocity Oxygen Fueled (HVOF) spray or Detonation Gun Coatings (D-Gun) are available.

Hard Chrome Plating

Industrial hard chrome plating is produced by electro-deposition from a solution containing chromic acid. The metal deposited on the base metal is very hard and corrosion resistant and improves the properties of the base metal. Feedscrews require a minimum of 0.001 – 0.003-inch coating for normal applications. The hard surface provides wear resistance for processes that do not contain high levels of abrasive fillers. The smooth hard surface also minimizes deposits from forming during processing and facilitates cleaning. Although the chrome coating is highly corrosion resistant, it is porous, and will only provide a minimal amount of protection from corrosive materials. It does not adhere to the hard surfacing alloys used for flight treatments.

Electroless Nickel Plating

Electroless nickel plating is used to deposit nickel without the use of an electric current. It is produced by the controlled chemical reduction of nickel ions onto a catalytic surface. This coating provides good resistance to corrosion and wear and can be applied in a uniform manner. It is typically used to improve corrosion resistance because it forms a non-porous coating on the screw base metal. The wear resistance is not as durable as chrome and it is difficult to obtain thick coatings.

Thermal Spraying

Thermal spraying is a process by which a spray of molten or semi-molten droplets is applied to a surface. Low-energy flame spray techniques are not suitable for screw coating applications due to poor adhesion. High-energy techniques such as High-Velocity Oxygen Fueled (HVOF) thermal spray, and detonation gun coating, (D-Gun®), have been successful. The HVOF process utilizes the combustion of oxygen and fuel gas to produce a high-velocity stream that is used to propel powders at supersonic speeds. The D-Gun® process developed by Union Carbide uses a spark discharge to detonate the oxygen fuel mixture used for acceleration of the particles. The surface finish obtained from this process is much rougher than the plating methods discussed above. A range of materials can be used for this coating process, which provides excellent corrosion resistance. Thermal sprays of stainless steel and nickel-based alloys are common. Coatings containing tungsten carbide have also shown good results.

These processes are only used when all other traditional methods have been exhausted due to the limitations of the application process and expense. It is also important to note that it is very difficult to obtain uniform coatings over the complex geometry of the screw and the direction of application is limited to the line of site. Sharp corners are typically brittle and difficult to coat. Other sophisticated treatment technologies such as vapor deposition and titanium nitriding have been used in a very limited number of applications.

We hope this series of feedscrew blogs has been informational for you. Any questions, please e-mail marketing at marketing@davis-standard.com.