In the previous blog, we covered basic characteristics of low bulk density materials and common...

Choosing the Right Machine for Your Reclaim Goals, Part I

Reclaim extrusion is a worthwhile pursuit for processors looking to achieve sustainable practices while taking advantage of cost savings from re-using available materials. What is the right machine for your reclaim objectives? In the first part of this blog series, we’ll cover the basic characteristics of low bulk density materials as well as various single screw extruder designs used in reclaim processes. In the second blog, we’ll discuss feed-assisted single screw extruders including a crammer feeder, ram stuffer and cutter compactor.

Due to the nature of plastics recycling, materials come in different forms and shapes. The most common include flake, fluff, pellets, chips, chunks and ribbons. The term bulk density refers to the weight per unit volume of the raw plastic material as it is purchased from the material supplier. In the world of plastic resins, bulk density is labeled in pounds per cubic foot (lbs/cu ft), grams per cubic centimeter (g/cc), or kilograms per liter (kg/l). Some of these materials are non-free-flowing due to irregular particle shapes, inconsistent bulk density, varying contamination levels, electrostatic charge, or moisture content. When conveying or feeding these materials, they may agglomerate into large masses that impede flow and create erratic throughputs or blockages. Thus, the need for reclaim technology that supports consistent materials conveying and processing.

When choosing a machine, it’s important to consider the feedstock form (particle size, material properties), the bulk density of the feedstock (in general the higher the bulk density, the higher the output rate), and the compressibility of the feedstock. Common reprocessing concerns include material contamination (soil, wood, paper, different types of plastics); contamination levels (by percentage); moisture content; availability of a consistent material stream; and if the equipment is capable of processing varied bulk densities. Following are the reclaim pros and cons of some common extruder designs.

Smoothbore single screw extruder: This is the most fundamental extruder choice with the lowest capital cost and greatest versatility. However, bulk density is critical and typically needs to be greater than 15 pounds per cubic foot. In terms of particle size, the aspect ratio must be smaller than the available feed opening. Small extruders (under 4 ½-inches in diameter) are limited in feed depth because of mechanical constraints so particle size reduction is critical to proper feeding.

Groove feed extruder: With the type of intensive grooves often found in an extruder designed for PE pipe extrusion, this type of extruder is best for specific medium-to-heavy reclaim materials that do not involve thermally sensitive plastics. Axial grooves in the feed section increase friction in the feed zone to improve feeding. The grooves will increase output over a standard smoothbore extruder and impart less shear temperature into the material. The material exits the extruder at lower melt temperature and downstream cooling requirements are reduced.

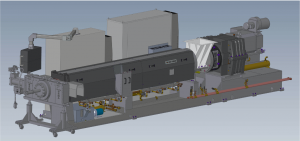

Wide mouth scrap reclaim extruder: Ideal for light to medium bulk density material, wide mouth extruders feature a 3 L/D tangential feed throat with a 30-degree feedsection opening to one side of the extruder. A grooved horizontal liner creates positive material conveyance through the feed section. This type of machine can be used for bulk densities from five pounds per cubic foot upward, although at densities under 10-15 pounds per cubic foot a ram stuffer can enhance performance significantly.

Dual diameter extruder: This extruder is used for very low bulk density products, such as foam, ranging from two to five pounds per cubic foot. It is engineered with two different diameter sections; a large feed section and a small extrusion section. The feed section is typically two extruder sizes larger than the smaller diameter section to allow for a high-volume feed area for compressible low bulk density materials. The small diameter section is fed by the large-diameter via the transition section. The small diameter section acts as a standard extruder performing feed, melting, mixing, venting and pumping functions. The feedscrew can be a simple metering screw or a complex barrier design depending on application.

We look forward to talking about options for feed-assisted single screw machines in the next blog. In the meantime do not hesitate to contact us for support or additional questions Stay safe and healthy!