What to Look for in a Blown Film Die – Blown Film Series Part III Brampton Engineering Die® In this...

Applications, Layers, and Equipment – Blown Film Series Part I

In the world of plastic films, there is a myriad of different applications that require carefully designed structures with between one and 11 layers of resin. Davis-Standard and its subsidiary Brampton Engineering offer a full range of blown film equipment and associated downstream equipment to address nearly every application. In this blog post, the first in the blown film blog series in 2020, we’ll highlight some common film applications and the associated equipment that goes along with them.

First, let us acknowledge that this is a huge marketplace with exciting options. Just within our organization, we support applications for agricultural, retail, industrial, medical, stretch and shrink products, and of course the largest and fastest-growing segment, flexible packaging for food and other consumer products. Some common examples include:

Plastic bags – These films are typically mono- or three-layer PE structure, and are processed on robust high-output equipment, often in-line with bag-making equipment. We are able to build lines where pellets enter one end and rolls of finished bags exit the other.

Agricultural films – This market includes everything from greenhouse coverings and silage film for wrapping bales of hay to mulch film used to cover fields and reduce evaporation of water and pesticides. These films can have up to seven layers and are made on extremely large lines with bubbles up to 25 meters in circumference.

Flexible packaging applications – Innovative and sustainable lightweight flexible packaging made with multi-layer blown film offers better product protection, consumer convenience, and shelf appeal while reducing the environmental footprint when compared to heavier alternatives.

Stand-up pouches, bags and many other flexible packaging formats use sealant films with an inner layer that melts and bonds easily to make a secure seal in the filling process. The sealant is co-extruded with other types of PE that can add stiffness, a moisture barrier, puncture resistance, toughness and necessary thickness at low cost. Barrier resins such as EVOH can contribute to longer shelf life for foods by preventing the passage of oxygen and flavor compounds.

Thermoformed and vacuum-sealed packages give proteins like whole and cut meats, sliced cold cuts, sausages, and cheese a much longer shelf life by excluding oxygen and contamination. These films often include nylon (PA) for toughness and formability.

Resealablility enables consumers to store the unused portion of the product safely until future use. In addition to zip-type seals and spouts on bags and pouches, multi-layer blown film allows the development of sophisticated easy-peel openings that can be reclosed – and also serve as an attractive package label. The top web of this package will include the sealant that bonds permanently to the bottom web, the pressure-sensitive layer that can be peeled open and reclosed, and the top layers that provide the necessary physical properties. Often this multi-layer, multi-purpose film structure is then laminated to a reverse-printed, stiff and glossy layer.

Considerations for Applications

The key is understanding what types of films your customer base needs now and in the future, and what type of processing flexibility is required within your product portfolio. The best equipment designs and features vary depending on the most complex films in the product portfolio. The good news is, we are prepared to advise you every step of the way. For the applications above, you need to consider:

-

- The maximum number of layers you might want to make (A five-layer film can always be made on a nine-layer line, but the reverse is not true.)

- Control system options for operational efficiency

- Best feedscrew designs for the types of resins to be used, including blends and additives (Our next blog post will dig deeper into resins.)

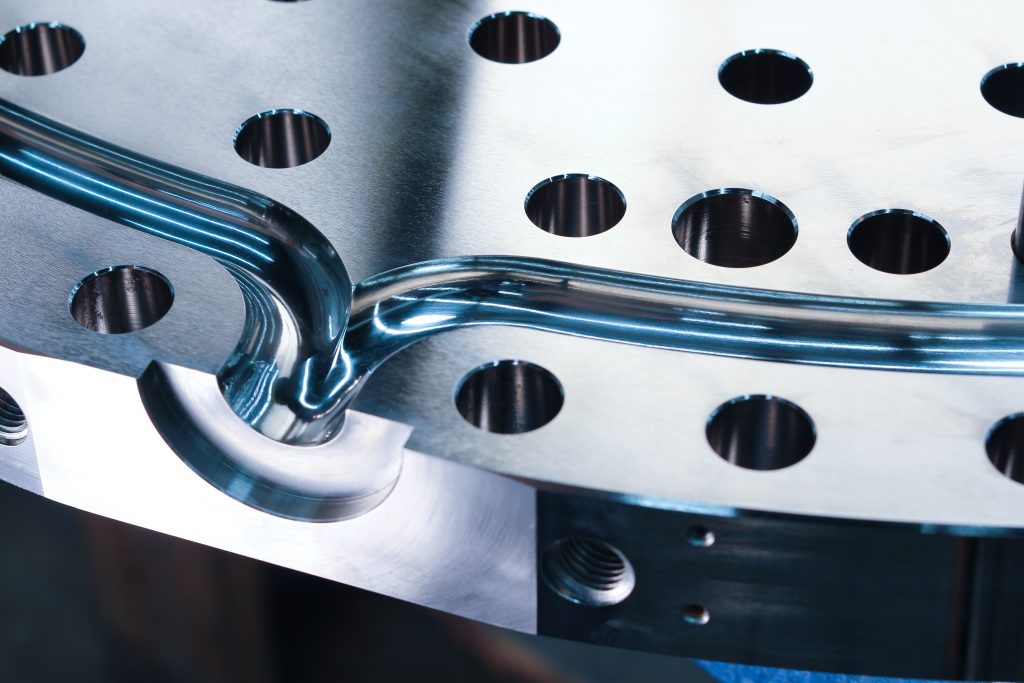

- Die design for evenly distributing and combining different melted resins. Achieve superb layer to layer thickness uniformity when using expensive raw materials; without any layer to layer crossover, is critical to manufacturing World Class Products. (The third in our blown film blog series will cover what to look for in a blown film die.)

- The air ring and internal bubble cooling system for controlling the inflation of the bubble and freezing in the desired properties (Our fourth blog post in this series will cover what to look for in an air ring.)

- A collapsing frame to flatten the cooled bubble into a wrinkle-free web

- A primary nip or haul-off at the top of a tower to pull the film at a controlled rate from the die before traveling back down to be slit, treated, or printed prior to feeding into the winder

- Winding technology or integrated downstream converting equipment

Have questions regarding this post? Please comment below.

If you’re looking for help navigating line design or upgrading your equipment to boost production goals, we have experts in all product areas here to help. Contact Marketing at marketing@davis-standard.com or visit our blown film page for more info.