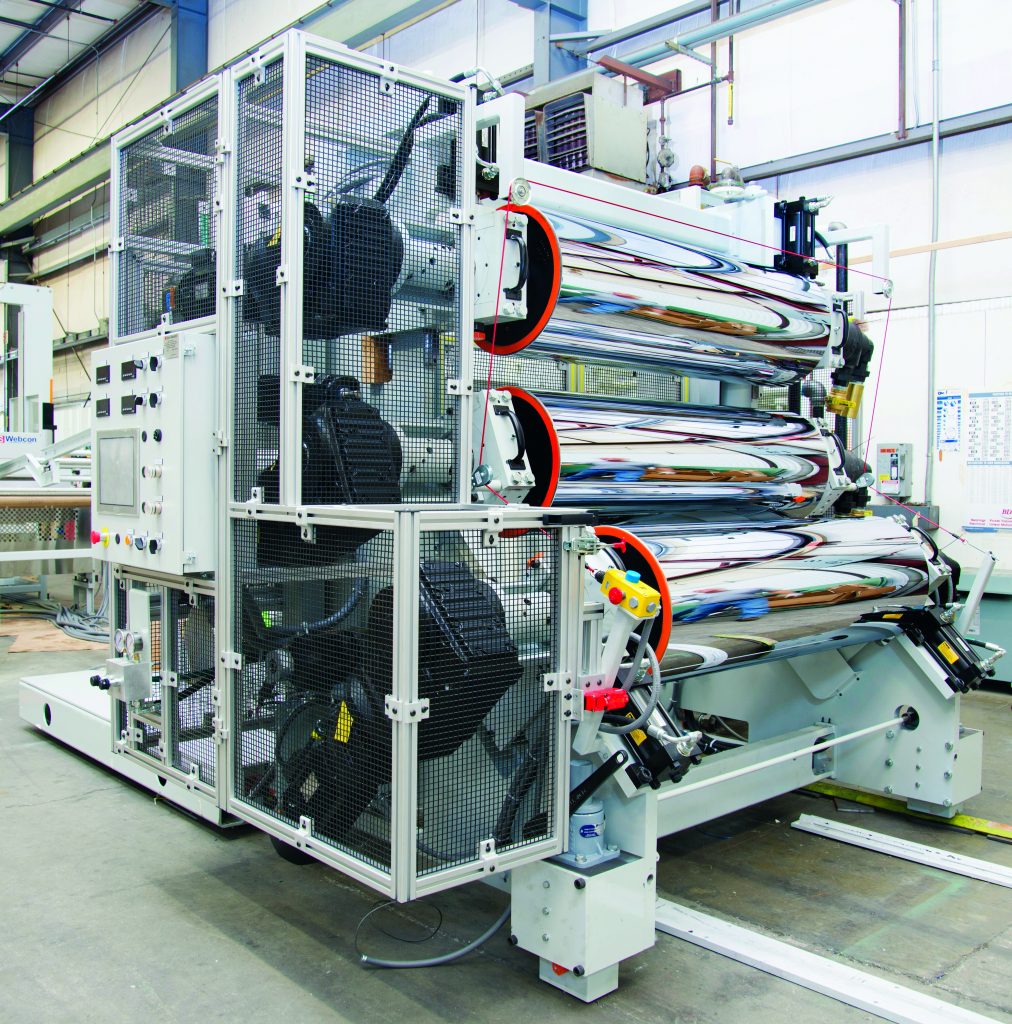

The new COVID-19 reality has placed PPE products front and center! PPE devices such as face shields...

Aligning Your Extruder = Protecting Your Investment

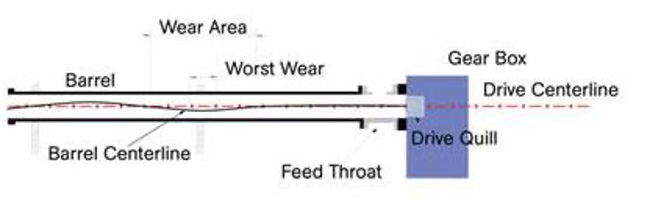

Is alignment important in order to optimize your extruder investment? You bet it is! And the longer the extruder barrel, the more significant alignment becomes. A poorly aligned extruder causes excessive wear and tear on both the screw and barrel. We’ve seen misalignment cause costly and unnecessary damage including premature wear, bent and broken screws, unstable barrels, heater crawl, thermocouple shearing, additional drive load, and die movement. In this blog, we’ll discuss the value of extruder alignment and why using a barrel support system is important to protect your investment. We have also included a boroscoping video at the end.

First, the barrel must be aligned to the driving mechanism, which is the drive quill of the gearbox. No exceptions. Trying to determine alignment by leveling is inaccurate as it is not indicative of the drive quill and only measures the vertical plane. The correct procedure involves using an optical or laser alignment scope inside the drive quill to align the barrel to a fixed center line by rotating the drive quill. The barrel and feed throat are then aligned to that center line by adjusting the barrel supports, or the mounting faces of the feed throat.

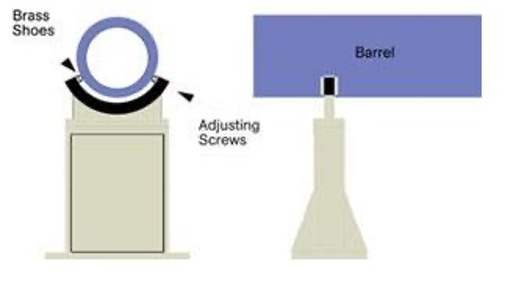

There are a number of quality support system designs available, but take note of the following considerations during selection. First, the barrel must be able to freely expand through the support(s) as it is heated without distortion. The barrel should never be locked down by a support that completely surrounds it. This prevents the barrel from having the necessary room to slide when expanding. Secondly, the support joints need to be made from non-corrosive materials, such as brass, which will prevent “freezing” of the support. Finally, the entire barrel support must be rigid enough to maintain its position rather than tipping over as the barrel expands. Steel expands at 0.000006 in./in.-°F, so a 4.5-inch 36:1 barrel at a uniform operating temperature of 450 °F grows 0.320 inches longer when heated from room temperature. If the steel can’t expand in a straight line, it will bend. This diagram shows how a two-point barrel support system allows for this expansion.

To see if your supports are working properly, open the covers and observe where the fresh mark on the barrel is relative to where the barrel slides through the support. If these do not closely correspond to the calculated expansion, there is an issue with your support system. It is also important to make some checks after the initial heat-up to ensure alignment. This can be done by placing dial indicators at 90-degree angles on the discharge flange to see if the barrel has significant deflection when heat is applied. Noticeable deflection can be caused by a support that is not functioning properly, unbalanced heating due to burned-out heater valves, half heaters around a vent, or structural weakness.

In general, the importance of aligning extruders 3.5 inches (90mm) or smaller is often considered redundant from the manufacturer’s original alignment; unless the L/D is exceptionally long. For larger or lengthier extruders, the bases are seldom rigid enough to hold the manufacturer’s alignment for a long period of time. We recommend using certified extruder alignment technicians to perform the service. Davis-Standard also offers barrel alignment services. The money spent on alignment will provide significant cost savings by helping you get the most out of your barrel and screw investment while ensuring peak extruder performance.

Do not hesitate to contact us if you need additional help aligning your extruder (select service in the Project Type drop-down menu).

Stay safe and healthy! For any other questions, e-mail marketing.